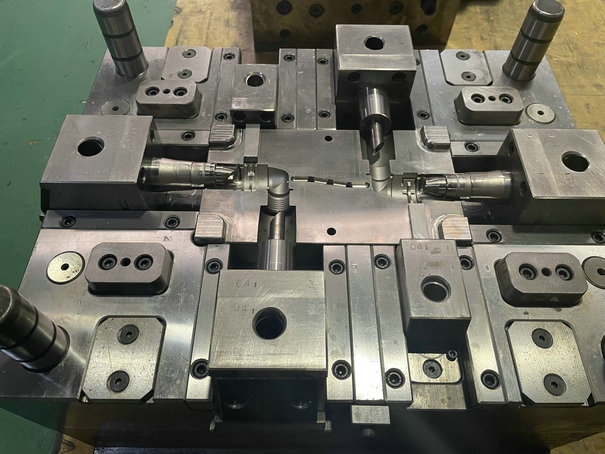

Air Poppet in injection mold (Automobiles & Vehicles - Auto Parts & Services)

USNetAds > Automobiles & Vehicles > Auto Parts & Services

Item ID 133178236 in Category: Automobiles & Vehicles - Auto Parts & Services

Air Poppet in injection mold | |

The popular design of injection mold is generally using the thimble to push out the mold of the product. For the products with high product appearance requirements, most of them do not adopt this way. Because of the reason of the product structure. The top block cannot be used for all products. For example, for a barrel, a product with a special structure of inverted buckling. The surface of the product is an external surface without perforation. If a general thimble is used to push out the product, it is easy for the product to be sucked. Resulting in the product being pushed out of a depression, or perforation occurs. Affect the appearance and use of the product. At this point, an air poppet is needed. The air poppet is completed to solve the shortcomings of the prior art. The purpose is to provide a product with a simple structure, convenient operation, suitable for this special structure of the barrel and basin, and improve the qualified rate of the product. Reduce production costs and make it easier for products to be completely ejected. Air pop valves are available in inch and metric sizes. They are designed to break the vacuum created when forming thin-walled or deep-drawn parts such as flowerpot trays and containers. Multiple air cone valves can be used for large or heavy-duty sliders.  | |

| Related Link: Click here to visit item owner's website (2 hits) | |

| Target State: All States Target City : All Cities Last Update : Sep 05, 2024 10:33 PM Number of Views: 134 | Item Owner : CNMOULDING Contact Email: Contact Phone: 021-52913487 |

| Friendly reminder: Click here to read some tips. | |

USNetAds > Automobiles & Vehicles > Auto Parts & Services

© 2025 USNetAds.com

GetJob.us | CANetAds.com | UKAdsList.com | AUNetAds.com | INNetAds.com | CNNetAds.com | Hot-Web-Ads.com | USAOnlineClassifieds.com

2025-08-27 (0.441 sec)