CNMOULDING-injection mold company (Automobiles & Vehicles - Auto Parts & Services)

USNetAds > Automobiles & Vehicles > Auto Parts & Services

Item ID 133794970 in Category: Automobiles & Vehicles - Auto Parts & Services

CNMOULDING-injection mold company | |

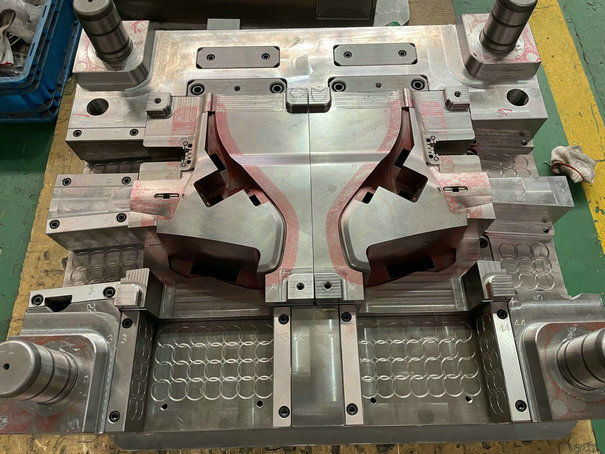

CNMOULDING-injection mold company project Management: Project management is the key to the success and quality of the products, All our Project Engineer not only has rich knowledge in tooling and injection molding but also speak good English. The project engineers will be responsible to follow up on the tooling process and timely reporting to the customer on any issues and progress of the project he is handling. All we do want is to provide: 1, On-Time Delivery 2, Assuring customer’s project is produced to customer’s standards and requests 3, Anything communicated in a timely and clear way 4, Complete project management and support from concept to final part inspection and approval. The Mold Standard: Mold Steel: ASSAB(Sweden), DAIDO(Japan),FINKL(America),AUBERT & DUVAL(France), Thyssen(Germany), LKM (China) Mold Base: EMP, DME, HASCO, FUTABA, LKM. Hot Runner: MOULD MASTER, SYNVENTIVE, HASCO, DME, YUDO, INCOE Standard Parts: DME, HASCO, LKM, HEB, STRACK, OPITZ Texture: VDI 3400, Mold-tech, Yick Sang, Tanazawa, etc Software:Pro/Engineer,Solidworks,AutoCAD,Moldflow, Unigraphics, CATIA, MasterCAM Mold making in-house : Our Mold shop is well equipped with advanced machines, such as High-speed CNC machines, Slow wire cut machines, and Mirror EDM machines, they are all imported from Taiwan, Switzerland, or Japan. they will make sure the mold is manufactured with high precision and a good finish. moreover, all processes in the house will ensure the short lead time of mold making, our shop has 30 skilled toolmakers, most of them have more than 10 years of experience in mold making, they are familiar with all machining processes, cost of each step and potential troubleshot for mold. I think they are the biggest treasure of our company, their experience, and hard work will be guarantee high-quality mold at a reasonable price. The concept of plastic injection molding Plastic Injection molding is used to produce many things such as wire spools, packages and bowls, bottle caps, automotive parts, toys, optics, some musical instruments (and parts of them), one-piece chairs and small tables, storage containers, mechanical parts (including gears), and most other plastic products available today. Injection molding is the most common modern method of manufacturing parts; it is ideal for producing high volumes of the same object. Injection molding uses a ram or screw-type plunger to force molten plastic material into a mold cavity; this solidifies into a shape that has conformed to the contour of the mold.  | |

| Related Link: Click here to visit item owner's website (0 hit) | |

| Target State: All States Target City : All Cities Last Update : Oct 10, 2025 3:58 AM Number of Views: 41 | Item Owner : injectionmoldchina Contact Email: Contact Phone: 021-52913487 |

| Friendly reminder: Click here to read some tips. | |

USNetAds > Automobiles & Vehicles > Auto Parts & Services

© 2025 USNetAds.com

GetJob.us | CANetAds.com | UKAdsList.com | AUNetAds.com | INNetAds.com | CNNetAds.com | Hot-Web-Ads.com | USAOnlineClassifieds.com

2025-10-30 (0.387 sec)